You’ve got the idea.

You’ve got the vision.

Now you just need the product.

When you source a product from a supplier, whether it’s local or (more likely) overseas, there are reasons to worry.

Pick an unprofessional supplier and you could waste hundreds of hours and have to restart. Or miss a mistake in your pre-shipment sample and you’ll be stuck with defective products collecting dust in your basement.

These are the kinds of crucial errors that Kian Golzari wants you to avoid.

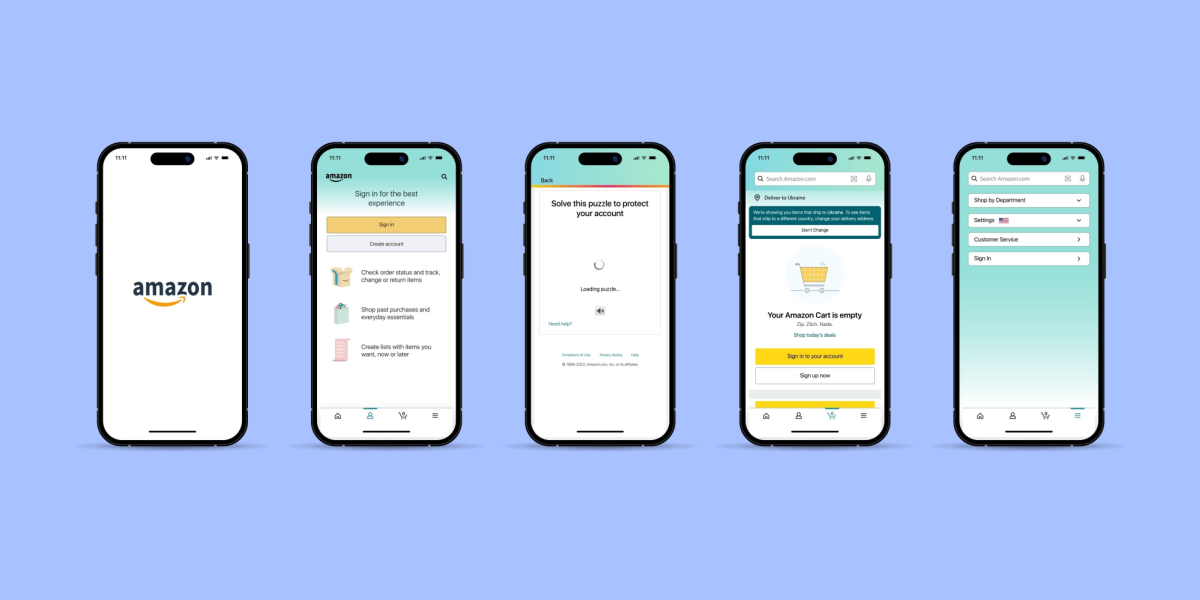

Golzari is one of the world’s top sourcing experts. He has manufactured products for top companies and NGOs, including Tesco, the United Nations, the 2012 Olympics, and Google. In all, he’s sourced more than 2,500 products and works with 100 of the top sellers on Amazon.

He’s also the instructor for two Foundr courses: The Product Development Blueprint and The Product Sourcing Blueprint.

Get Golzari’s four-step product sourcing strategy below.

How to Source Products in 4 Steps

Before we get into the details of product sourcing, let’s get clear on a few key terms. The terms manufacturer and supplier are sometimes used interchangeably. That’s because a manufacturer can be a supplier, but a supplier isn’t always the manufacturer.

- A factory is a physical location where products are assembled.

- A manufacturer is a business that produces products from raw goods.

- A supplier sells finished products directly to retailers and outlets.

When you take your first step searching for suppliers and manufacturers, typically you’ll reach out to a supplier that either contracts or works for the manufacturer.

Golzari says to plan out 100 days to be safe when sourcing your product. That timeline will include everything from finding a supplier to getting your first shipment.

Here’s his timeline for you calendar addicts:

- 10 days to find a suitable supplier online

- 2 weeks for sampling

- 2 months for production

- 30 days for shipment

Now, onto the steps.

Step 1: Find the Wrong Supplier First

A mistake Golzari sees from early-stage founders is committing to the first supplier that meets their requirements on Alibaba, the world’s most popular product-sourcing platform. He says you still could be overpaying even if you negotiate the price. That’s because people don’t take the time to know the value of the raw materials.

“Let’s say I identify the top five suppliers I want to work with. I would also find a list of the top five suppliers I don’t want to work with, and I’m going to ask them all my questions to learn about the product,” Golzari says.

“I would also find a list of the top five suppliers I don’t want to work with, and I’m going to ask them all my questions to learn about the product.”

You can learn more about your product’s potential materials by interviewing low-grade suppliers. Get samples from them. Deconstruct the products and understand the impact of each raw ingredient on the product’s performance.

“So if you have an outdoor chair for your garden, online they look the same, but they’re different prices. And one might be polyester fabric, one might be nylon fabric,” Golzari says. “[You] can now think, ‘There are 30 different places where I could actually improve the quality without maybe adding so much cost.’”

From that information, create a product specification sheet and reach out to your top five suppliers.

“They’re not going to mess you around with the price because they know you know about the product, but you learned it from the suppliers you didn’t want to work with,” Golzari says.

Once you’ve chosen a supplier, start building a relationship with them. Golzari gets their WhatsApp information and regularly sends texts and video messages, sometimes with a friendly greeting.

“Now I’ve got video communication with my supplier through the app, and I’ve built that relationship,” Golzari says.

After building a relationship with the supplier over the product development process, Golzari even asks for a video tour of the factory the day before they ship out.

“So now you’ve got eyes and ears inside the factory and [are building] that relationship,” Golzari says.

This also gives you a chance to vet the working conditions in the factory. Aim to partner with suppliers that treat their team members well.

Don’t Skip: New Product Development Process in 8 Easy Steps

Step 2: Sample and Sample Again

Golzari says sampling is one of the most critical product-sourcing steps. You get two types of samples from a supplier: the preproduction and pre-shipment samples.

The preproduction sample comes before committing to a manufacturing process, and the pre-shipment sample comes before the orders are shipped. Golzari says before you commit to shipment, both samples should line up perfectly.

After receiving the preproduction sample, you should test the product as much as possible in case you need to make tweaks.

“You are your own toughest critic of the product. That’s first. Once you’re happy with it, you might want to send it off to a third-party company for legal and product testing if it’s required,” Golzari says.

“You are your own toughest critic of the product. That’s first.”

He suggests also getting influencers or community members involved in testing your sample product.

“Get the influencers involved in the initial stage, and then they’ll be more compelled to share it with their audience when it’s launched,” Golzari says.

Another tip is to keep every sample you’ve made to compare quality over time. Write the purchase order number on the product’s label. That way, you can know which order has an issue if you have a bad batch.

Step 3: Inspection

Before sending your hard-earned cash to a supplier, you must get a third-party inspection of your products. Golzari says the most important thing to look at on the inspection report is the AQL (acceptable quality level).

Three types of defects might turn up on an inspection: minor, major, and critical. Each shipment cannot exceed the maximum percentage threshold of all the products in order to pass inspection.

- 4 percent for minor defects

- 2.5 percent for major defects

- 0 percent for critical defects

For example, if you were creating a children’s scooter, a minor defect would be scratching, a major defect would be the handlebars are too small, and a critical defect would occur if the wheels don’t work.

If your inspection fails, you have to do a reinspection. Golzari says the factory should pay for the reinspection because you paid for the initial one.

Golzari says if you get a failed inspection report, don’t freak out.

“Sometimes inspection companies can be overly harsh and overly critical. At the end of the day, you’re paying the inspection company, not the factory,” Golzari says. “The important thing is not to freak out when your product fails. Sometimes it’s actually absolutely fine.”

Dive Deeper: Your Guide to Product Packaging Design and Strategy

Step 4: Order and Iterate

Golzari says one of his consistent mistakes is spending too much time perfecting the product before launching. He says that comes from perfectionism and a fear of getting copied.

“The window of opportunity could actually pass because while you’ve spent so much time developing [a product], other people have launched their version as well,” Golzari says. “So I always say develop until a product is 80 percent ready because it could take maybe a few weeks to get that from zero to 80 percent, but it could take nine months to a year to get it from 80 to 100.”

He suggests working on the final 20 percent while your product is selling.

“A lot of people are worried if someone copies their product. Well, if they copy your product, they’re copying what is already out there, so they’re copying what you’ve already made, but you’re working on the newer version,” Golzari says. “So by the time they bring that copied product to market, you’ve brought out your newer version. So as long as you stay innovating, stay on top of your products, you’ll always be one step ahead of the competition.”

Keep Learning: How to Find a Manufacturer That Won’t Burn You

Start Product Sourcing for Your Business

By following Golzari’s blueprint, you’ll be more comfortable sourcing products again and again.

“It’s kind of like reps in the gym. The more you do, the stronger you get, the more samples you develop, the more suppliers that you talk to—you just get better at it,” Golzari says.

“The stronger you get, the more samples you develop, the more suppliers that you talk to—you just get better at it,”

Golzari says sticking to the details is well worth it, especially when you see your product making a real difference in your customers’ lives.

“The proudest moments I’ve had is when I’ve had products [that took] long hours, late nights in the factory making those products, and I’ll just see someone wearing it down the street, and they’ve got no idea [who made it],” Golzari says. “When I see that, it’s the best feeling in the world.”

The feeling of curiosity that Golzari had as a kid when his dad returned from China with a new product is the same feeling that drives him today. With his blueprint, you can do the same. And when you know you’ve followed the right process, that feeling will be even more special.