Poor experiences with shipping can cost you customers, sometimes even before the sale is complete. But great experiences lead to repeat business. Of course, we all want to deliver those great experiences, but man, it can cost a lot.

It’s hard to focus on one operational aspect like shipping, and put the time into figuring out how to improve customer satisfaction in a cost-effective way—especially when things like product availability and the next big product update or release all seem more pressing and exciting.

However, the warehouse improvements you make now can impact every single product you offer and what products you can offer in the future. Investments in shipping are investments in longevity.

So here are our four favorite ways to reduce customer shipping costs, all with a clear line to giving customers a better experience and hopefully generating more recurring revenue over the long term.

1. Work With Multiple Carriers

A growing business will usually work with whichever carrier offers the best deal on its first set of orders. A company will price out their initial run and then establish a relationship with that winning carrier. From there, it’s either running things down to the nearest store or using online tools to print labels and order pickup.

Set. Forget. Keep moving.

That’s a smart strategy for the early days, when you’re never sure about orders and want to be able to drop off a package at the end of the day. It has flexibility baked in, but it doesn’t have growth included. The problem is that you might have gotten a great deal from FedEx, UPS, or even USPS flat-rate items on that first round of packages, but they could be the wrong carrier for your next round.

Or, they could be the wrong carrier for a small subset of your packages, depending on size, weight, and distance. Plus, when you grow large enough, carriers offer volume-based discounts. The exact amount you’ll save and eventually pay is based on location, volume, and your packages too.

There’s no specific guarantee, so you’ll need to approach each carrier individually to get their price or to understand what volume you need to reach to qualify for a deal.

If you are able to negotiate deals, you’ll still need to compare each package rate to find the smartest option. Your best bet is to use software that can automate decisions based on price or other factors you choose. Any leading warehouse management software (WMS) package will be able to use established dimensional weight (DIM) and billed weight calculations for carriers and apply your discounts, then automatically pick the best option for your shipments. Get help choosing the right WMS option for your business by consulting this guide.

If you’re not at a high enough volume to receive a discount and you’re having other shipping and fulfillment issues—like inaccurate orders that lead to a lot of returns—look for a fulfillment outsourcing partner. These third-party logistics providers (3PLs) typically have deals with carriers already in place and get a reduction based on their total volume across all clients, helping you save.

Start by searching for them online (it’s as easy as starting with Google), and looking for one that specializes in your industry or product category. Logistics-focused message boards, chats, and social media channels can also be a big help. The right channel will depend on your needs, but there are plenty out there, including Reddit’s /r Truckers, the IWLA library, Trucking Boards, and many more that you can find via search, associations, or asking your team members.

Remember, not every 3PL will be a good fit for your business. Talk with potential partners to make sure you feel comfortable with their service and how they respond to questions. Check out this page for help learning how to choose a great partner based on your company size and product demands.

2. Reduce Your Zone

If your first business was like ours, there’s a lot you discover about a warehouse and shipping the hard way. One of the biggest surprises to us was the existence of shipping zones. They make sense when you think about it, but most people need a little nudge to engage with the concept.

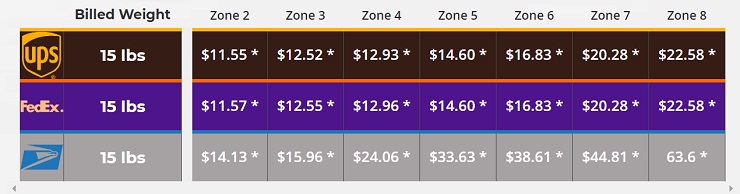

A shipping zone is a geographical area that carriers use to designate how far something is going to travel domestically, impacting the price. The further something travels, the greater number of zones it crosses and the more you pay. Zones are typically measured by groups of zip codes.

They are generally searchable so you can use them to plan for costs and other concerns. For example, there’s this domestic zone chart from USPS.

What this boils down to is that you pay more when packages travel further, and these costs grow when your packages get heavier or go further. For example, the cost of shipping a 30-pound package more than doubles when you compare shipping to Zone 2 and Zone 8.

You can’t change where your customers live, so the end location is fixed. However, you can work to change the origin point, dramatically reducing zones a package will travel.

Some companies do this by having one location in the central United States. Others, including our company Red Stag Fulfillment, operate two or more locations to quickly serve major cities on each coast as well as the interior.

The “how to” for reducing your zones can be a tricky conversation to start. First, you’ll want to determine the average zone distance you’re shipping to and the average cost per order, plus your current order volume.

Let’s say you’re shipping six zones away on average and your standard order is 30 pounds of billed weight. That’s $59.03 per order. If you could cut that down to three zones by adding a new warehouse (whether you run it or a partner does), that would be a reduction of $26.49 per order. If you’re filling 1,000 orders per month, that’s $26,490 of savings.

If a second warehouse generates that level of savings and costs less than that per month, it’s definitely worth considering. And, if the second warehouse allows you to deliver to customers faster, it could also potentially help increase your revenue too.

These calculations will definitely depend specifically on your business. However, knowing the areas you ship to can make it easy to find large distribution centers in nearby zones, which often does lead to significant savings when you’re a high-volume business.

3. Reduce the Size and Weight of the Package

Now let’s go a little deeper on your individual orders. Not only can you shave off costs by reducing how far they travel, but also by reducing bulk and size in the packaging you choose.

Consolidating multiple products or orders into a single package means shipping less. However, it’s rare that individual customers are going to be placing multiple orders all at once. So you want to reduce elements for these individual orders.

The box itself and the materials you use to fill it are the next targets to consider. First, let’s think about the box you use right now, whether it’s custom or standard. Ask yourself these questions about your average order:

- What box and filler materials do we use?

- Do we always use the same box?

- Do we always use the same amount of filler materials?

- Are box selection and packaging up to the person who is packing the order, or do we have a standard?

- Could we go smaller without our product getting damaged during shipping?

- Do our customers enjoy opening the boxes we ship, or do we get strange looks when a tiny product comes inside a huge box by itself?

One of the most common packaging mistakes we run across is companies putting products in boxes that are too large. First off, your customers don’t like dealing with all that extra box. Second, oversized boxes require more infill to ensure the product inside isn’t damaged. Third, you could end up paying more than you need to because of all that extra space. DIM weight pricing can penalize you significantly if the product inside is light, but the box is huge.

Go small. When possible, arrange things tightly to limit movement and damage, while cutting costs. Then, fire up a DIM weight calculator to see what your price changes are. Here’s some package types with their usage and dollar comparisons.

You should also look at your infill options to see what’s needed for your product and where you might be able to save. Some locations are even starting to ban materials like packing peanuts, so pay attention. Here are a few fill options to consider:

- Kraft paper: This is the brown paper you commonly find in packages because it is cheap, recyclable, easy to use, and offers decent protection.

- Air pillows: Growing in popularity, air pillows are extremely light and are a smart choice for products that need a lot of infill, while offering some protection.

- Bubble wrap: A staple for delicate items, bubble wrap is dense and protective, with multiple size options to give you flexibility. Plus, who doesn’t like popping a few?

- Foam wraps: A little on the expensive side, some foam wraps work well for fragile products where you don’t have a lot of extra room. The foam is thin and versatile, but not recyclable.

- Shredded cardboard. Recyclable, sturdy, and often available around the warehouse. Shredded cardboard can add some weight to a package, but it is very protective, easy for customers to remove, and affordable.

There are plenty of options to help you protect your products while making it easier and more enjoyable for customers to open them. If you’re worried about delighting while also switching to green materials like shredded cardboard, ecommerce businesses can add extra touches like inserts, custom tape, colored tissue paper, and stickers that make your customers think of you.

Dropping the cost of shipping each package by reducing packaging costs can make it easy to add in these finishing touches without impacting your bottom line.

4. Choose a Warehouse in Your Region

Delivery speed is important to everyone, and you can manage a lot of related concerns when you’re a regional business. The best thing when starting out is to choose a warehouse or fulfillment partner that is in your area and can deliver to your local customers quickly.

The closer your warehouse is to your production lines, the faster everything can get out the door and get to customers. By reducing the distance here, you’re also paying less in shipping because you’re controlling those pesky shipping zones.

Nearby warehouses are also easier to inspect and manage costs. Your team will know the local regulations and there are fewer concerns about crossing borders or addressing multiple municipalities for shipments and labor concerns. In most cases, you’ll already have some experience with building and leasing considerations in your area too.

Closer locations also tend to mean cheaper trucking options if you outsource and less risk of running afoul of the Transportation Department’s hours of service requirements—drivers are restricted in how much they can drive and when. This is tricky to assess and monitor correctly, as many recent legal cases can show you.

Here, the gain to you and your customers is speed and reliability. Fewer things can go wrong in shorter distances and it’s easier to expedite orders or work a little more one week and get things out the door.

Finalizing the warehouse location decision does require a few additional items that may slightly expand your zone of consideration. Ensure that the facility you choose is large enough to house your inventory as you grow. It should also be located close to a large enough labor force to make staffing available and affordable. The average commute time in the U.S. is 27 minutes each way, which is a good number to try and stay under for your employees.

If you’re going to use a third party, we like local options, simply because it’s always easy to visit and evaluate how your goods are being stored and shipped. Here’s a little help for choosing the right city for your warehouse or business.

Don’t Rush Your Shipping Decisions

Learning how to improve your shipping involves making smart choices for your operations. These decisions are going to take time to properly research and find the right partners and staff to help you execute.

Don’t rush. Taking your time and making the right decision can save you countless hours and into the hundreds of thousands of dollars.

In the warehouse, small changes add up quickly, whether you’re cutting costs with materials, improving delivery times, or launching a new location that gives you slightly better margins on each package. Your business is worth the time investment to get things right.

Share this with someone who needs to read it, and comment with your best tip below to help others get the answers they need. Any questions? I’m happy to help.